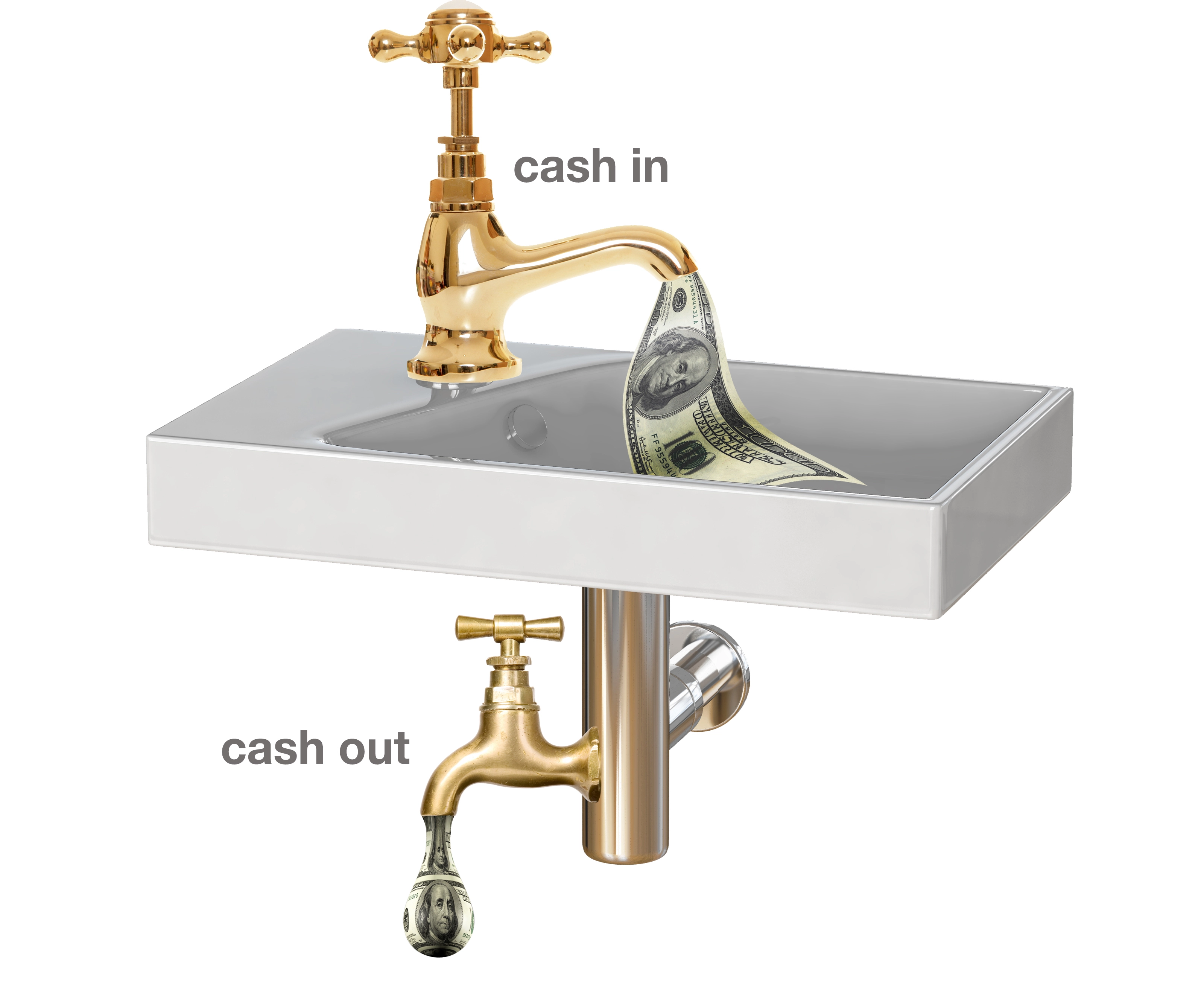

Last month, I gave you the second step: Know your overhead cost per hour for each department. When you calculate your overhead cost per hour, your cost might seem high. What do you do to bring it down?

First, what is a reasonable overhead cost per hour?

For smaller companies, service overhead cost is $60 per hour or less. The more billable hours you have, the lower your overhead cost per hour. If you have at least 5 technicians billing at least 1,800 hours a year, your overhead cost per hour should be $40 or less. For large companies (over 20 technicians), overhead cost per hour it can be under $25.

Replacement/project overhead cost per hour should be under $30, and new construction should be under $20.

If your overhead cost per hour is too high, billable hours are the first place to look.

On average, employees work 40 hours a week or 2,080 hours a year. Assuming you deduct vacation, holidays, meeting time, and training time, you can only sell about 1900 hours a year…about 91% of the employee’s time can be sold, i.e. billed.

How many hours a year per employee do you actually sell?

If your billable hour percentage is less than 75% for service or less than 85% for replacement, your overhead cost per hour will decrease as you increase billable hours.

Here are five ways to increase billable hours:

1. Service technicians go to their first call from home except for meeting days. Their time starts when they arrive at their first call. If they have been coming to the shop, this gives you an extra 30 minutes to an hour of billable time each day. Your revenues increase, and your bottom line increases, too.

2. Dispatchers route efficiently. They decrease the amount of travel time wherever possible, and they send the right technician to the right job.

3. Replace parts from what the technicians use on the job. Most software packages have the ability to create a list of parts that you use daily. Each technician has a “locker” where they can replace parts. They pick them up when they come for meetings.

4. Lock up the warehouse. Equipment/materials are ready for the crews when they arrive in the morning. They should be in and out of the building in 15 minutes or less. Crews do not get to pick and choose what they need for the jobs. If they do, they always take more!

5. Stagger the start times for the crews. This helps ensure that they get out within 15 minutes of arrival.

If your billable hours are in line, make sure that overhead contains only overhead expenses:

1. Make sure credit card/financing fee expenses are not in overhead. These expenses are the cost of goods sold expenses. You don’t have a credit card or financing fee unless you sold something.

2. Make sure that payroll for field employees is in cost of goods sold. Your CPA often puts all payroll in overhead to make it easier for him or her to prepare your taxes. It is not correct from an operational P&L standpoint.

3. Make sure other income and expenses are after net operating profit. This means that interest you receive on bank balances, late fees or nonusual expenses such as the sale of a truck are accounted for after net operating profit. The bottom line is the same. However, do not include these nonoperational expenses in overhead.

4. Make sure that commissions and SPIFFs are part of the costs of goods sold. They are expenses because you sold something. They should not be included in overhead.

5. If you give bonuses at the end of the year – don’t include these payroll expenses in the overhead calculations. These are not part of normal operations. You give them to share the wealth after a profitable year.

6. If you have building renovation expenses, they are not part of regular operating expenses and should not be included in overhead expense calculations.

7. Consider depreciation expenses as an overhead cost. If they are not included, your overhead cost per hour will be slightly lower than it should be.

What if none of these seven situations occur in your business? Then, take a good look at overhead expenses and look for areas you can cut. Or can you add additional billable hours with another field employee? Remember that this field employee needs to have 1,800 billable hours a year, whenever possible, to be totally productive.

If your billable hour percentage is less than 75% for service or less than 85% for replacement, your overhead cost per hour will decrease as you increase billable hours.

Ruth King has more than 25 years of experience in the HVACR industry and has worked with contractors, distributors and manufacturers to help grow their companies and become more profitable. Contact Ruth at ruthking@hvacchannel.tv or at 770-729-0258.