There is increasing global activity to transition to more climate-friendly refrigerants to meet the growing demand.

There are similarities and differences in refrigerant classes and the potential risks they introduce, so it is important to be aware of differences and to follow current best practices that apply to all refrigerants:

- Most refrigerants are heavier than air and can displace oxygen. It is important for emergency and maintenance planning to have adequate ventilation and to be aware of refrigerant and oxygen concentrations in machine rooms and other confined spaces, especially in commercial systems, to minimize the risk of exposure. The metric used by ASHRAE is the Refrigerant Concentration Limit (RCL). The RCL for A1 refrigerants is set to exposure limits, but for flammable refrigerants, the RCL is set at 25 percent of the lower flammability limit. This metric sets the safety requirements and allowable charge limits for all refrigerants, including A1 and A2L refrigerants.

- Nearly all refrigerants are either flammable or combustible and all fluorocarbon-based refrigerants produce hydrogen fluoride (HF) when burned and as compressed gases can cause frostbite if liquid refrigerant is sprayed on skin. All refrigerants should be isolated or removed from equipment where work is being performed to minimize releases and potential exposure.

- Proper personal protective equipment must be worn to minimize exposure from breathing vapors and exposure to HF and minimize risk of frostbite.

- This list is not all-inclusive. See refrigerant producers’ safety data sheets (SDSs), the equipment service manual or reference training for more information.

- Although low GWP refrigerants directly reduce emissions of greenhouse gases, the energy efficiency of systems and equipment also is important to reduce indirect environmental impacts due to emissions from power generation.

Writing on the Wall

The Montreal Protocol for Substances that Deplete the Ozone Layer, ratified in 1989, phased out two classes of ozone depleting refrigerants - chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs). Hydrofluorocarbons (HFCs) replaced CFCs and HCFCs in many applications to reduce damage to the ozone layer but are potent greenhouse gases. The most commonly used HFC refrigerants for air conditioning and commercial refrigeration (R-410A and R-404A) have thousands of times the climate impact of carbon dioxide.

The greenhouse gas impact of HFCs has been well understood for decades. Countries, states and local jurisdictions began regulating HFCs and seeing a pending patchwork developing, the impacted industry agreed to support the global phase down of HFCs using the same orderly approach as was used to phase out ozone-depleting substances (ODSs).

In 2016, the parties to the Montreal Protocol agreed to phase down the use of HFCs citing, among other concerns, the continued increase in refrigerant usage and emissions that are expected to rise as access to refrigeration and air conditioning continues to increase in developed and developing nations.

The Kigali Amendment to the Montreal Protocol is now in force, having been ratified by more than 90 countries and is designed to reduce the production and consumption of these heat-trapping gases more than 80 percent over the next 30 years. A certain percentage of these refrigerants needs to remain to service existing equipment and for use in refrigerant blends.

Low GWP Refrigerants

Refrigerants in widespread commercial use that replace CFCs, HCFCs and HFCs can have different toxicity and flammability properties. It is important to understand how to mitigate potential hazards through their proper handling, storage and use.

The transition to low global warming potential (GWP) alternatives will result in greater usage of refrigerants that were traditionally used prior to the development of CFCs (e.g., ammonia, carbon dioxide and hydrocarbons such as propane and butane) and to new alternatives with different properties than products currently used today.

Refrigerants are classified by ASHRAE based on toxicity testing and flammability characteristics.

ASHRAE has RCLs for all ASHRAE 34-listed refrigerants in consideration of toxicity and flammability properties. Building codes have traditionally adopted ASHRAE 34, ASHRAE 15 and other safety standards that provide guidance regarding mitigation if the charge size of the refrigerant would be installed in a space where the RCL would be exceeded.

As mentioned above, for A1 refrigerants, the RCL is set in ASHRAE 34 based on exposure limits, but for flammable refrigerants it is conservatively set at 25 percent of the lower flammability limit LFL. For example, if the concentration might exceed the RCL limit that creates a toxicity, asphyxiation or flammability concern in a machine room, sensors and ventilation or other mitigation are required.

These requirements were already in ASHRAE 15 prior to the evaluation of low GWP refrigerants and have been modified and updated in the new ASHRAE 15-2019 as a result of industry research and testing.

EPA SNAP Program

The Environmental Protection Agency (EPA) Significant New Alternatives Policy (SNAP) Program is required by statute to maintain a list of “acceptable” and “unacceptable” substitutes for ozone depleting substances (ODS), including refrigerants replacing HCFC-22.

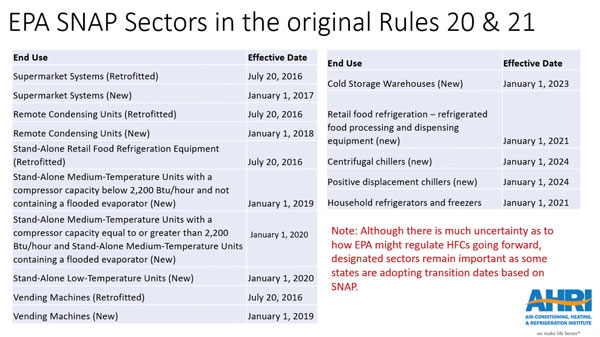

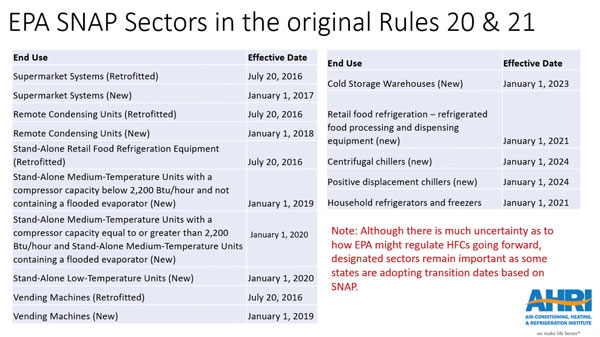

In 2015 and 2016, the EPA promulgated regulations (SNAP Rule 20 and 21) changing the status of several high global warming potential (GWP) refrigerants to “unacceptable.” In Mexichem Fluor, vs. EPA, refrigerant producers Mexichem Fluor and Arkema challenged the legitimacy of SNAP Rules 20 and 21.

The D.C. Circuit Court determined that EPA was still responsible for maintaining the list of substitutes for ODSs, but EPA could not regulate the use of previously accepted alternatives that were not ODSs. The SNAP Rules 20 and 21 were remanded back to EPA to be re-written in compliance with the Court’s decision.

The D.C. Circuit Court determined that EPA was still responsible for maintaining the list of substitutes for ODSs, but EPA could not regulate the use of previously accepted alternatives that were not ODSs. The SNAP Rules 20 and 21 were remanded back to EPA to be re-written in compliance with the Court’s decision.

EPA SNAP Rules 20 and 21 remain important as several states are adopting the requirements in those regulations directly or as mandated by statute.

EPA Refrigerant Management Section 608

EPA also updated Section 608 of the Clean Air Act (CAA) to include requirements around venting, leak reduction and reporting for HFCs in 2016. The National Environment Development Association Clean Air Project (NEDACAP) and the Air Permitting Forum (APF) petitioned the courts to review the recent changes to Section 608. In response, EPA published a new rule in 2020 rescinding leak requirements for HFCs.

The Paris Climate Agreement

Parties to the Paris Climate Agreement agreed to limit global temperature rise to 2C, with an aspirational goal of limiting the increase to 1.5C. Sixty-five (65) countries committed to address high global warming potential HFCs in their Individual Nationally Determined Contributions (INDCs) to the Paris Agreement.

U.S. Climate Alliance

On August 4, 2017, the U.S. submitted notification of withdrawal from the Paris Climate Agreement, withdrawing, at the earliest, Nov. 4, 2020. The United States Climate Alliance States committed to reduce emissions commensurate with the original U.S. commitment. 444 “Climate Mayors” also committed to the Paris Climate Agreement reductions.

Since the U.S. has not yet ratified the Kigali Amendment, some states have included HFCs in this effort.

There is increasing global activity to transition to more climate-friendly refrigerants to meet the growing demand. In the U.S. 16 members of the Climate Alliance are working to address consumption and/or emissions of HFCs as part of their efforts to reduce greenhouse gas emissions.

California Air Resources Board (CARB)

California Senate Bill 1383, signed into law in 2016, mandates HFC emission reductions of 40 percent by 2030, compared to 2013 levels and requires that CARB create regulations to meet this goal. The rest of the world regulates based on refrigerant production and consumption rather than emissions.

Since California’s goals are based on emissions from equipment that has been in place for 15 to 30 years, California’s goals are 5-10 years ahead of the Kigali Amendment.

To meet this ambitious goal, California adopted the EPA SNAP rules by regulation and legislation and the EPA CAA Section 608 Refrigerant Management rules by regulation. CARB proposed a transition date for air conditioning (AC) equipment to low GWP refrigerants in 2021.

In response to the 2017 proposal, AHRI, its members and the Natural Resources Defense Council, proposed that CARB delay the transition date to 2023 to align with U.S. Department of Energy’s new energy efficiency requirements to eliminate an additional transition and has requested a further delay until 2025 to allow for sufficient time for building codes to be updated.

As of September 2020, CARB is drafting regulations that may require a transition of commercial refrigeration refrigerants to those below 150 GWP in 2022 and air conditioning refrigerants to those below 750 GWP by 2023. California is also considering a ban on the use of refrigerants above 1500 GWP for use to service equipment.

Implementation Varies by Country

As noted earlier, under the Montreal Protocol each country can adopt their own regulations. There are generally four primary strategies used to regulate fluorocarbons, which are sometimes combined:

- Carbon taxes (used in Australia from 2012 – 2014)

- Quota and allocation system (Canada, Europe, Japan)

- GWP limits by sector (Canada, Europe, Japan)

- Refrigerant ban by sector (U.S. and most countries for ODSs)

There are some variations to these and some ancillary requirements.

- Australia has a step down every two years instead of every five years as required under the Kigali HFC Amendment.

- Australia requires a refrigerant deposit which is refunded for returned HFCs to encourage good refrigerant management.

- Japan has reclaim refrigerant requirements

Safe Refrigerant Transition

Differences in low-GWP refrigerant properties (e.g., flammability and toxicity) may require changes to current practices to minimize risk while meeting climate regulations. Some low-GWP refrigerants have not been used in some time or will be used with larger charge sizes (e.g., ammonia and hydrocarbons).

Some other low-GWP refrigerants are in earlier stages of commercial use (R-32 in EU, Japan and Australia air conditioning; R-1234yf in automotive air conditioning in US, Canada, EU, Japan and Korea). Other low-GWP refrigerants are being proposed for commercialization.

In 2012, in Australia, a carbon tax of $23 Australian dollars per ton was the impetus for a very quick conversion to low-GWP refrigerants. The Australian industry has yet to find incidents related to A2L refrigerants. The difference may, at least in part, be attributed to the analysis completed by stakeholders of the Australian supply chain and the new requirement that a license is required to purchase an HFC.

If interested in the Safe Refrigerant Transition Task Force, you can contact Helen Walter-Terrinoni (HWalter-terrinoni@ahrinet.org) or Christopher Bresee (CBresee@ahrinet.org). Visit ahrinet.org/SafeRefrigerant for additional information.

The D.C. Circuit Court determined that EPA was still responsible for maintaining the list of substitutes for ODSs, but EPA could not regulate the use of previously accepted alternatives that were not ODSs. The SNAP Rules 20 and 21 were remanded back to EPA to be re-written in compliance with the Court’s decision.

The D.C. Circuit Court determined that EPA was still responsible for maintaining the list of substitutes for ODSs, but EPA could not regulate the use of previously accepted alternatives that were not ODSs. The SNAP Rules 20 and 21 were remanded back to EPA to be re-written in compliance with the Court’s decision.