New digital manifolds and smart devices have most important features for refrigeration technicians.

As a leading supplier of refrigeration tools and components, REFCO knows exactly what refrigeration technicians need. Electronic measuring instruments for pressure and temperature as well as digital manifolds are well established on today’s market, with leading manufacturers offering entire series in their product ranges.

Requirements vary around the world — some refrigeration technicians rely on tried-and-tested devices while others prefer to use the latest technologies. And it’s important to meet both types of needs. The most important features of electronic measuring devices have been established in broad-based customer surveys and are discussed in more detail in this article.

Survey of 600 refrigeration technicians

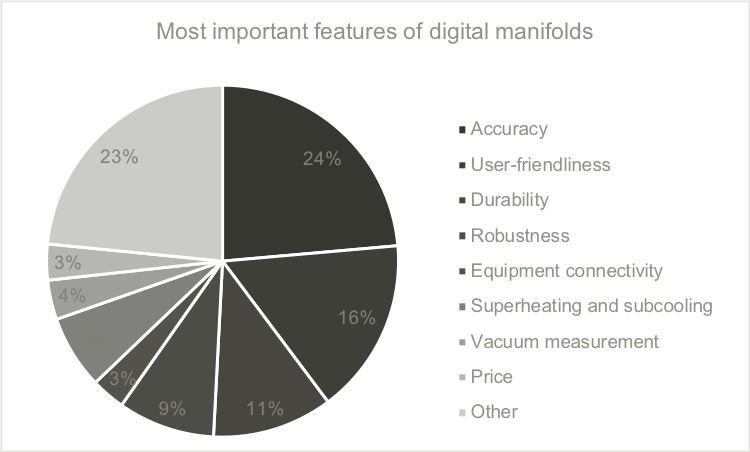

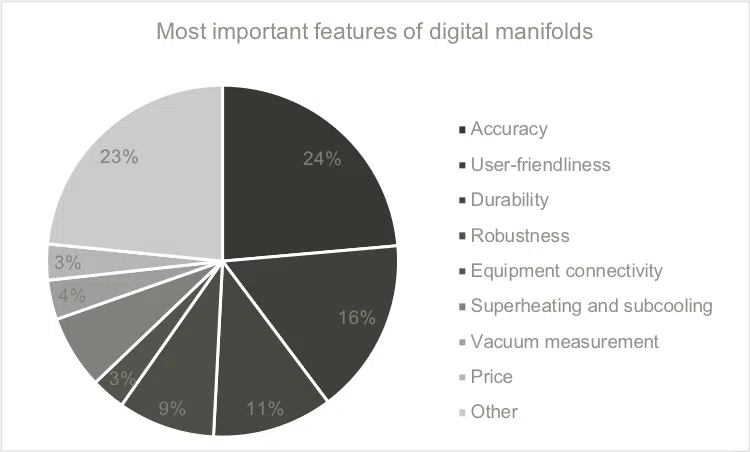

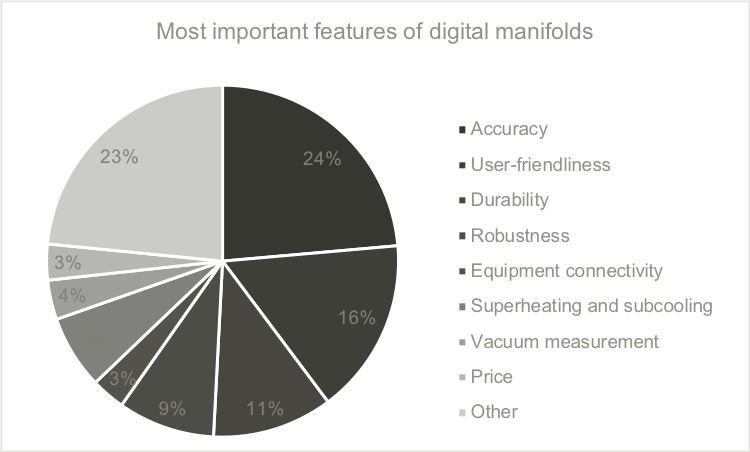

A survey of 600 digital product users has revealed the features considered most important in a digital manifold. To a certain extent, these results can also be applied to other digital products. As the pie chart shows, refrigeration technicians consider accuracy and user-friendliness to be the most desirable features in a digital manifold.

A survey of 600 digital product users has revealed the features considered most important in a digital manifold. To a certain extent, these results can also be applied to other digital products. As the pie chart shows, refrigeration technicians consider accuracy and user-friendliness to be the most desirable features in a digital manifold.

Accuracy of electronic devices

What matters when it comes to accuracy? The display value should obviously deviate only minimally from the effective value. However, accuracy of 0.5% is more than sufficient when installing a refrigeration system. The accuracy of pressure sensors on a manifold is specified as full-scale accuracy.

Therefore, the measured value may deviate by 3.6 psi from the effective value in a scale range of 0-725 psi, which results in a maximum temperature deviation of +/- 1°F in the calculated evaporation temperature for R410. Furthermore, users shouldn’t be dazzled by an unnecessarily high number of digits after the decimal point. What’s more important is the accuracy of the pressure measurement technology, which is achieved using instrument-specific calibration and reliable compensation for temperature influences.

User-friendliness

An intuitive user guide helps refrigeration technicians to quickly familiarize themselves with the manifold and to organise their workload efficiently. Frequently used controls can be activated quickly with just a few clicks. And when a device offers lots of functions, smart menu navigation is required.

Durability

A digital manifold is used continuously over several years. Therefore, it’s likely that sometimes it will be dropped, given a good shaking while in the service vehicle and used regularly with dirty gloves. The unit will also be exposed to occasional spray water, although it’s not designed for underwater use. So obviously the components chosen for use in the manifold must be extremely robust and durable.

A manifold must also be able to adapt to rapidly changing legal requirements. For example, it must be possible to update refrigerants following their release by the manufacturer, while firmware updates introducing new functions are essential. Wear parts must be readily available and easy to replace. From the refrigeration technician’s point of view, durability also means that they can keep the manifold for a long time: an anti-theft mechanism protects the device during long-term use.

Robustness

The device must remain operational and functional even in varying and demanding environmental conditions, something only push buttons can guarantee. Faced with environmental conditions that range from very low temperatures in deep-freeze systems to roof installations at >104°F, and the use of bare hands and dirty gloves, any touch display will reach its limits. An impact-resistant case helps protect against shocks and vibrations. The soft surface of the device itself also absorbs shocks and makes it pleasant to handle.

Equipment Connectivity

Everybody’s talking about IoT. It’s led to manufacturers offering devices with Bluetooth Low Energy (BLE) together with a free app for mobile devices. But what are the benefits of these apps for refrigeration technicians? If the apps simply display the same values as the manifold and allow the units to be set, then they are no more than gimmicks. The units will be adjusted by a technician at most once, during commissioning.

An app is only really useful to refrigeration technicians if they can record the measurement data that they generate using the manifold in a report. Ideally, all devices required for reporting would be connected via BLE and all relevant data collected in one report per installation or maintenance job. This would allow refrigeration technicians to quickly demonstrate the value of their service to their customer, save time and give them access to years’ worth of maintenance data. It also means that reports could be created seamlessly from several media sources.

This way of working will significantly change how services are provided — refrigeration technicians need to make sure they keep pace with these new developments. Refrigeration systems often have no access to a mobile network, and mobile devices or service tablets are not always charged, which means that it must be possible to connect multiple devices even without a mobile device. Measuring instruments that don’t display the measured values are therefore no use.

Superheating and Subcooling

Superheat and subcool values need reliable refrigerant data to be calculated correctly, helping the refrigeration technician to get the best out of the refrigeration system for normal operation. This should also be easily possible for a combined system with cooling and heat pump. The refrigeration technician should be able to check the superheat and subcool values without having to disconnect and reconnect the hoses.

Vacuum Measurement

Before filling, a refrigeration circuit must be correctly evacuated and the successful evacuation confirmed by the vacuum measurement. Some manifolds have cabled vacuum sensors. The vacuum measurement must be taken at the point on the refrigeration circuit furthest from the connection point of the vacuum pump, resulting in a big enough reach from the manifold to the vacuum measuring point. The range of the cables is often too small. A wireless vacuum gauge solves this problem.

Price

The above-mentioned features of today’s digital manifolds offer significantly more value to refrigeration technicians than those of earlier-generation manifolds. When comparing manifold prices, the scope of delivery should always be taken into account — some sets include vacuum and temperature sensors or temperature clamps and various models of hoses in addition to the manifold itself.

A survey of 600 digital product users has revealed the features considered most important in a digital manifold. To a certain extent, these results can also be applied to other digital products. As the pie chart shows, refrigeration technicians consider accuracy and user-friendliness to be the most desirable features in a digital manifold.

A survey of 600 digital product users has revealed the features considered most important in a digital manifold. To a certain extent, these results can also be applied to other digital products. As the pie chart shows, refrigeration technicians consider accuracy and user-friendliness to be the most desirable features in a digital manifold.