Profitable contractors do two things extremely well: Manage labor and manage inventory.

Labor management looks at billable hours for field personnel and the productivity ratio discussed in last month’s column (Review Timely, Accurate Financial Statements Each Month).

Inventory is a bet. Companies bet their hard earned dollars that when they purchase a part, equipment, or other materials that the company can sell what has been bought.

Look in the company trucks and in the warehouse to see if good or bad bets were made.

Inventory is a double-edged sword: residential companies must have stocked trucks to take care of customers’ needs immediately.

Commercially, customers are generally willing to wait to replace parts unless it is a critical part for a hospital, computer room or plant. In these cases, temporary heating or cooling is brought on site until the required part has arrived.

First, the company has to track inventory. I’ve seen it the same value on the balance sheet until the count at the end of the year. This is NOT a good way to track inventory:

A smaller contractor used this method of tracking inventory. At the end of the year, when he counted it, the difference was $10,000. This $10,000 was additional material expense that affected his bottom line — the company earned $10,000 less than he thought.

Another larger contractor didn’t count inventory for two years. The warehouse was “the wild, wild west” with field personnel taking what they thought they needed for jobs. When it was finally counted, the inventory value was $250,000 less than the value on the balance sheet. The company lost a quarter of a million dollars in value instantly.

How could that be? Because $250,000 in two years was $125,000 per year; $2,403 a week, or $13.74 per day for the 35 crews and technicians who touched inventory every day.

It’s easy to damage, lose or take an extra $13.74 per day to jobs and customer homes.

Track it and count it yearly. Spot check it monthly. Then, if the inventory doesn’t match, dig deeper.

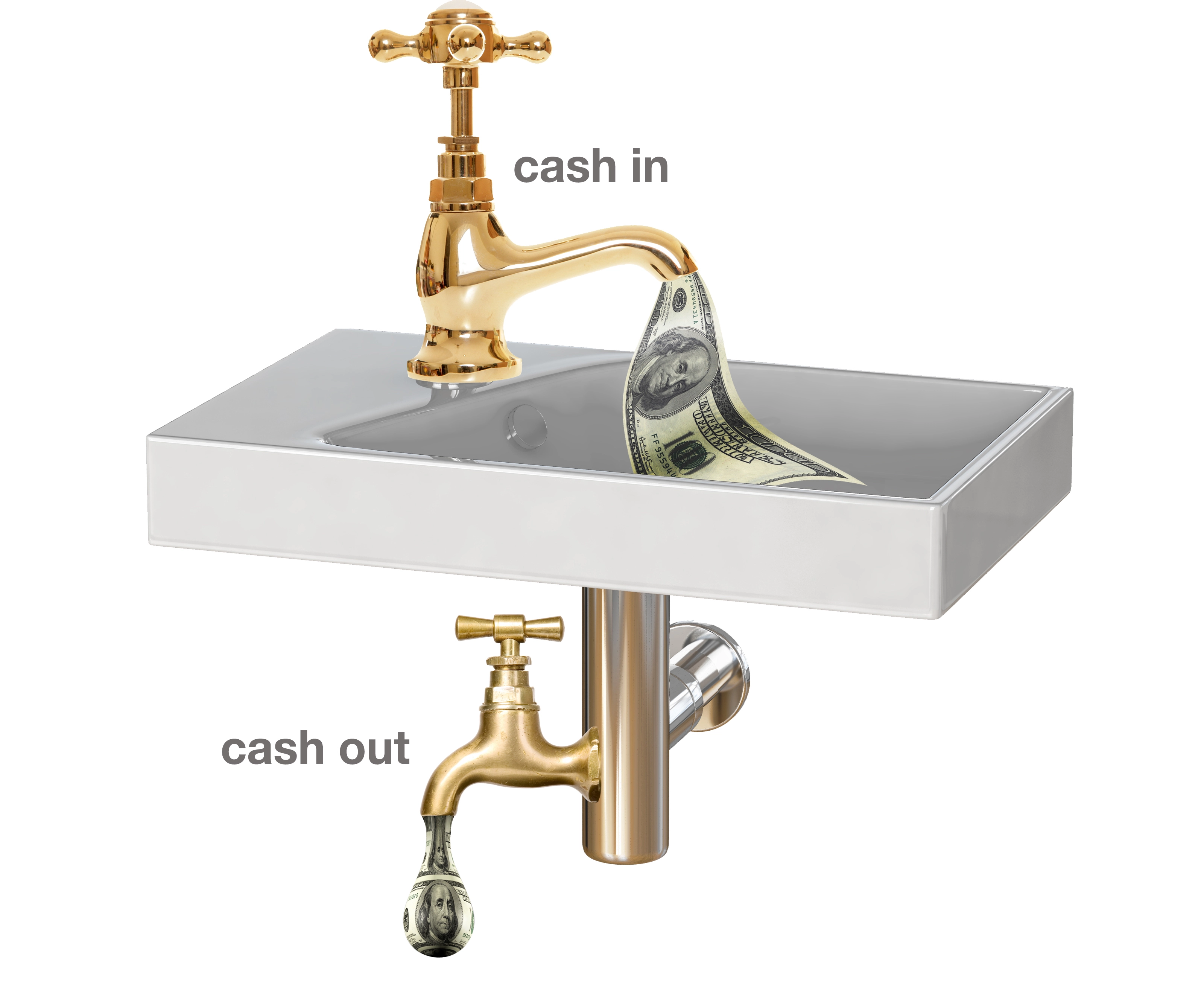

How much is too much inventory? First, look at the spread between current ratio and acid test lines.

If the two lines are parallel, then the company is usually using inventory well. If the two lines are getting wider apart, then inventory is building up.

Second, if inventory days are increasing, this should be a warning sign that either a seasonal stocking order has been placed or excess inventory is being purchased.

Here are seven procedures to put in place so that inventory becomes less of a bet:

1. Lock up the warehouse! Eliminate warehouse supermarkets where field personnel can take whatever they want for a job or their truck. Lock up refrigerant and service parts separately. If materials are taken out of the stock room, what was taken is recorded (most simply) on a piece of paper and transferred to that technician’s truck stock.

2. Bar code. Barcoding software has become inexpensive. Barcoding easily tracks what material comes in and out of the warehouse and what material is used on jobs and service calls.

3. Use purchase orders for all materials. If the equipment/materials are ordered for a sold job or service, then these materials never hit inventory. They go directly to material expense. At the end of the month, make sure the inventory was received (packing slips should be attached to the purchase orders) and matched with the vendor invoices to ensure the company is paying the proper price for materials.

4. One person is responsible for all inventory. If multiple employees on equal levels have access to inventory, then responsibility for accurate inventory is impossible.

5. If a service technician goes to the parts house for a part, the purchase order for that part is made part of the service ticket. If the materials are used from his truck, these materials can automatically be transferred out of inventory to material expense through industry software.

6. A material sheet for jobs is required. Inventory can be pulled for each job and be ready for the crews to take it to the job. Or, for multiple day jobs, it can be delivered to the job site.

7. Materials not used on the jobs are returned to the warehouse with a return material sheet.

Make sure your company places good inventory bets.