I walked into the warehouse for the first time at a new client’s business. His company could have been a supplier! He had enough parts and equipment to satisfy the needs of several HVACR contractors in his town.

Not only did it take up space, he never used all of the equipment in a year. There were many pieces stored from two, three and even four years prior. And yet, he still bought more. One of the first things I implemented was a ban on purchasing new parts and equipment until the existing equipment/parts were used.

Yes, if there was a special part or piece of equipment needed, that piece could be ordered. It never hit the warehouse since it went directly to a job. Suppliers hated the ban. His cash flow loved the ban, however, and he emptied the warehouse of parts and equipment.

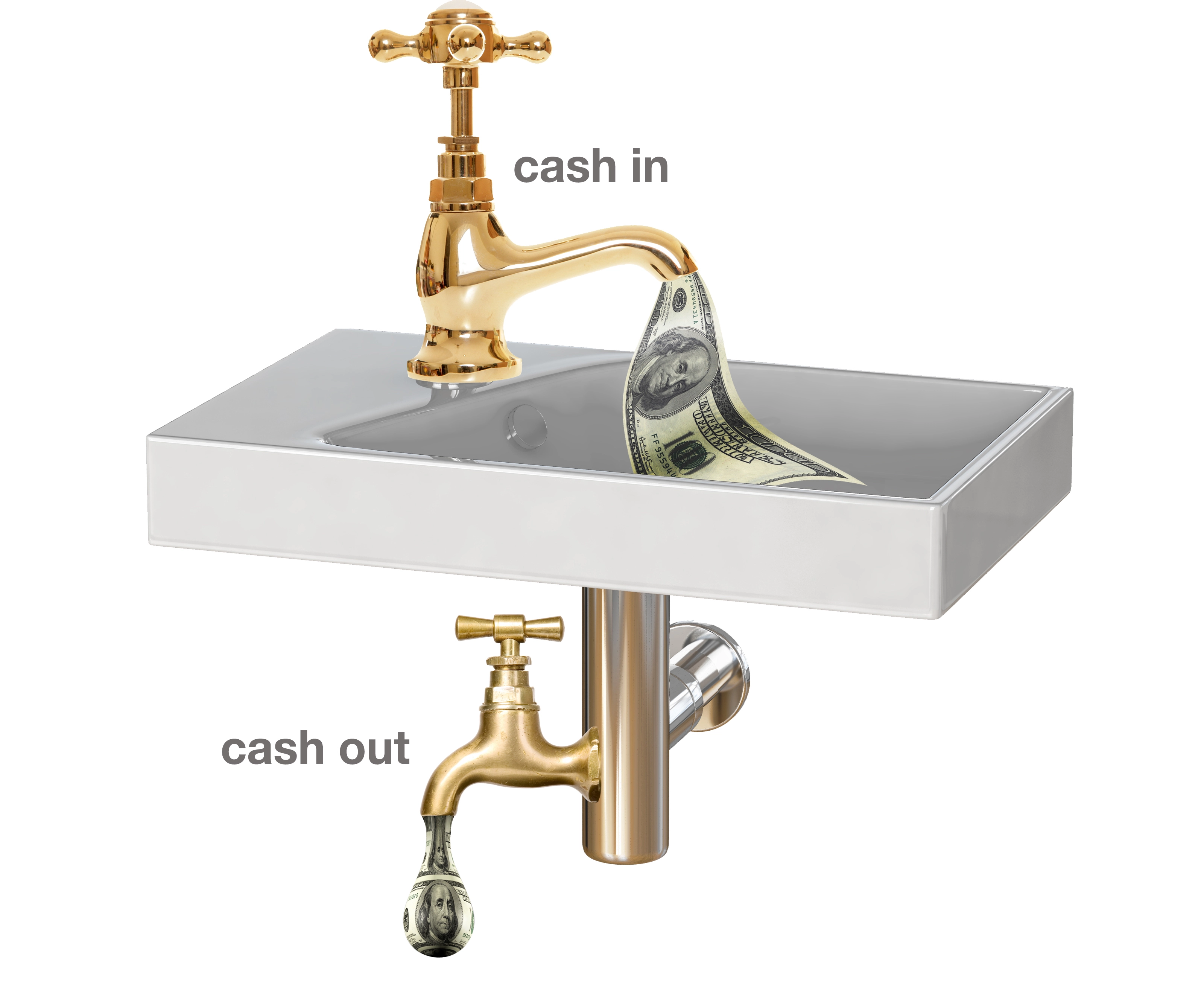

Inventory is a bet. You’re betting your hard earned dollars that you will be able to sell parts and equipment that you buy and store in a warehouse or on trucks.

Here are seven ways to improve your warehouse and inventory productivity.

No ‘Warehouse Supermarket’

This means installers and service technicians do not have access to the inventory. They don’t pick their own materials that “they think they need” for a job. These materials are picked for them and put in a specific location in the warehouse.

If employees have access, they will always take more than they need. And, these parts disappear. They are left on jobs, get damaged in trucks, and more of your hard earned dollars are wasted.

Lock Up Parts

All of your service parts should be locked up. This is usually a separate room in the warehouse. Some companies have even begun locking up refrigerant separately from service parts.

The locked room can be keyed with only certain people holding the key. Some companies have keypads to enter the room.

Each technician has a unique code to enter the room. So, if they need to come to the warehouse to get a part on a weekend, then someone with a key does not need to meet them there. They write the part(s) they took on a clipboard paper located near the door or they barcode the part(s) used.

Inventory Trucks

All trucks should have standard inventory. Each truck can have different inventory depending on the type of work the technician is performing.

Technicians only performing maintenance will have different standard inventory than those performing residential service, or those performing commercial service.

Materials are replaced based on what the technician used. Most service software can print out a list each day of what a technician used on a job. This list can be used for replacement.

Barcoding

The costs for bar coding have decreased dramatically and bar coding is now very affordable for contractors. This saves time because you just bar code materials/equipment coming into the warehouse and bar code materials/equipment going out of the warehouse.

Print out a list and you have your material expenses for the day, week, month or year. You can easily check the list against total job cost on your profit and loss statement to ensure they match.

Designate Staging Areas

The materials and equipment for each job should be placed in a specific area of the warehouse. This is the only area in which the crews are allowed.

Once all of the materials and equipment have been gathered, the crews go to the specific area for that job and can quickly load them into their trucks. This saves time and increases job productivity.

Staggered Start Times

If all the crews arrive at the same time, it takes much longer to load equipment. The staging area is too crowded and everyone stops to talk, even if it is only a two-minute conversation.

If crew start times are staggered by 15 minutes, each crew can get their materials out of their staging area, loaded on their truck and be gone by the time the next crew arrives.

Warehouse Responsibility

There should be one person who has control over the warehouse. He or she is responsible for all materials in and out.

Inventory discrepancies are this person’s authority, accountability and responsibility. If several people have control, then no one is in charge. This causes chaos, loss of productivity and loss of profits.

Ruth King is president of HVAC Channel TV and holds a Class II (unrestricted) contractors license in Georgia. She has more than 25 years of experience in the HVACR industry, working with contractors, distributors and manufacturers to help grow their companies and make them profitable. Contact her at ruthking@hvacchannel.tv or call 770-729-0258.

Ruth King is president of HVAC Channel TV and holds a Class II (unrestricted) contractors license in Georgia. She has more than 25 years of experience in the HVACR industry, working with contractors, distributors and manufacturers to help grow their companies and make them profitable. Contact her at ruthking@hvacchannel.tv or call 770-729-0258.

Ruth King is president of HVAC Channel TV and holds a Class II (unrestricted) contractors license in Georgia. She has more than 25 years of experience in the HVACR industry, working with contractors, distributors and manufacturers to help grow their companies and make them profitable. Contact her at

Ruth King is president of HVAC Channel TV and holds a Class II (unrestricted) contractors license in Georgia. She has more than 25 years of experience in the HVACR industry, working with contractors, distributors and manufacturers to help grow their companies and make them profitable. Contact her at