A company owner went to a job site a few days after the job was completed. The homeowner had not moved in yet and he wanted to check the job prior to a family living in the home. He was shocked at what he found: sheet metal, materials and trash in the basement. This was material that was paid for and could have been returned — material that could have gone back into inventory. Dollars spent that could have been used on another job.

At another company, one unscrupulous technician (who was fired) decided he didn’t want to do maintenance that day. He threw the filters in a nearby dumpster and disappeared. Higher material cost on that call because of a double filter order. This action caused lower profitability on that maintenance agreement.

Have you found materials on jobs that should have been returned? Materials that could have been used for another job, but no one was paying attention? As a result, money is wasted and profitability decreases.

This is the first of seven ways to increase installation productivity — return materials at the end of a job. It’s one of the quickest ways to increase your bottom line. Less wasted materials means more on the bottom line.

Here are six additional ways to increase installation profitability.

Eliminate Warehouse Supermarkets

No one, other than the warehouse supervisor and his direct reports, should have unrestricted access to the warehouse. If field personnel can choose “what they want,” these field personnel will always take more materials than they need, “just in case.”

At the end of the day or the job, these are the wasted materials that get left on job sites or damaged, rolling around in trucks.

Most software can print out a list of all parts used by a service technician on a specific day. This is the list of materials that gets ordered or pulled out of the warehouse, to replace on a technician’s truck. The technician doesn’t have to take his time to make a list and take more than he needs.

Lock up your warehouse. Increase profitability.

Material Sheets for All Jobs

And a corollary — all paperwork must be complete (with pictures) before starting a job.

Whoever sells a job is responsible for creating an equipment/materials list for that job. This includes all of the parts needed to successfully install that equipment. For larger commercial jobs, there always is a “take off” so a materials list can be electronically generated.

The sales person must take pictures of the proposed job. Include the existing equipment, where the new equipment is to be placed (if different from the existing equipment), as well as any unusual ductwork, working spaces, and other things that are helpful to the installation crews.

Pictures get the crews ready for the jobs. They can see what they will be doing and can ask questions as appropriate before they get to the job. This saves time, which saves dollars.

Eyes and Ears Open

You might think your technicians don’t have anything to do with installation. In fact, many technicians are the ones recommending a new system be installed. The customer probably trusts the technicians more than they trust a sales person.

Technicians can pick up their parts when they turn in their paperwork. I’ve seen much higher closing ratios for sales where the service technicians recommended replacing equipment.

The more referrals you get from technicians, the higher your sales closing ratio. Less burned leads, less wasted time, and higher closing ratio means more profitability.

Job Length Expectations

Everyone should know how long a job is supposed take. At the start of any job, the field personnel should know how many hours were included in the estimate. They need to know that the job should take 8 hours or 16 hours, etc.

If they don’t know what is expected, a one-day job can easily turn into a day and a half or two-day job. In busy times, this causes havoc with a schedule as well as the bottom line.

Stay and Finish

If it is going to take an extra hour to finish that day, then do it. Coming back the next day will eat at least four hours. One hour of overtime is less costly than stopping work, leaving a customer uncomfortable for another night and coming back the next morning to finish the job.

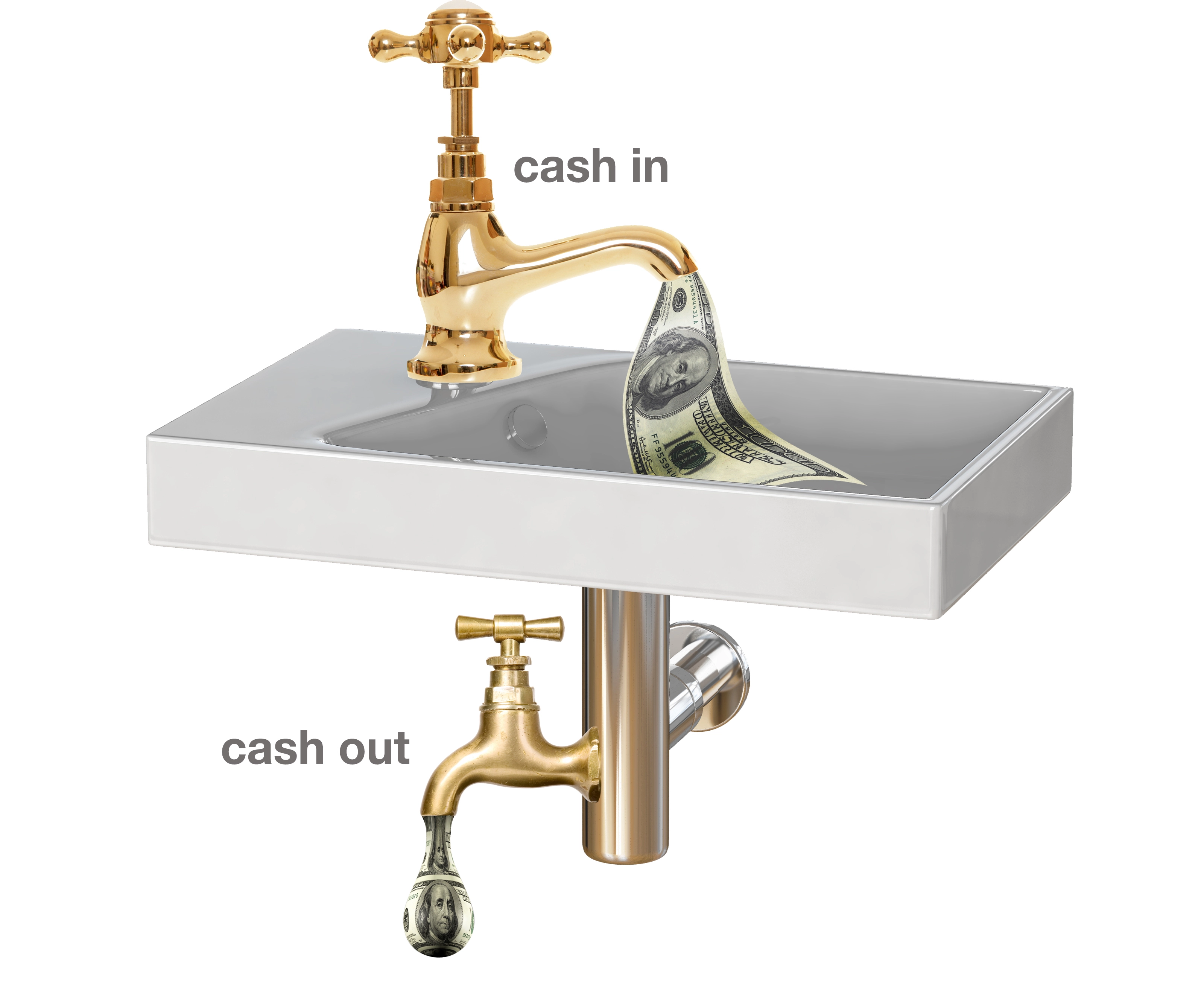

Watch Your Gross Margins

Increases or decreases could mean that someone is stealing materials from you. Consistent gross margins mean that jobs are coming in on time and on budget, inventory is not treated as a material expense and that you don’t have revenues in one month and expenses for those revenues in another month (Understand Your P&L: Gross Margin, May 2015, pg. 26).

If none of these things are happening then you may have material theft. This is not pleasant to think about but happens too often to hard working contractors who would never believe that one of their employees is stealing from them — until it happens.

Ruth King is president of HVAC Channel TV and holds a Class II (unrestricted) contractors license in Georgia. She has more than 25 years of experience in the HVACR industry, working with contractors, distributors and manufacturers to help grow their companies and make them profitable. Contact her at ruthking@hvacchannel.tv or call 770-729-0258.

Ruth King is president of HVAC Channel TV and holds a Class II (unrestricted) contractors license in Georgia. She has more than 25 years of experience in the HVACR industry, working with contractors, distributors and manufacturers to help grow their companies and make them profitable. Contact her at ruthking@hvacchannel.tv or call 770-729-0258.

Ruth King is president of HVAC Channel TV and holds a Class II (unrestricted) contractors license in Georgia. She has more than 25 years of experience in the HVACR industry, working with contractors, distributors and manufacturers to help grow their companies and make them profitable. Contact her at

Ruth King is president of HVAC Channel TV and holds a Class II (unrestricted) contractors license in Georgia. She has more than 25 years of experience in the HVACR industry, working with contractors, distributors and manufacturers to help grow their companies and make them profitable. Contact her at