The Hidden Value of Ultraviolet UV-C Light for Commercial HVACR Applications

When Niels Ryberg Finsen (1860-1904) found that bacterial infections healed more rapidly in the presence of Ultraviolet energy (UV) from the sun, the scientific community began to study it in earnest. In the early 1900s the first UV water purification facility was installed in Marceau, France. This was a major milestone in proving the efficacy of UV against microorganisms.

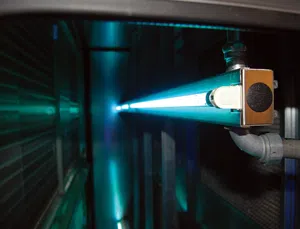

Today, the largest use for UV-C involves the world's number one consumable — water. Light energy in the ultraviolet-C (UV-C) wavelength (253.7 nm) from lamps disassociates elemental bonds in organic matter, effectively killing and degrading microbes much like UV light from the sun degenerates many types of materials, such as vinyl and rubber. In the early 1930s UV-C lamps were commercialized by Westinghouse and GE and became widely available.

Since the 1940s, UV-C's ability to kill microorganisms has led to many different types of applications in a variety of industries.

For example, during the 1950s, Tuberculosis (TB) outbreaks in the United States were on the rise and many of today's antibiotic cocktails were not available. Since several papers supported the effectiveness of UV-C against TB, UV-C lamps were installed in the upper-air section of hospital waiting and patient rooms, etc. and related air handling units (AHUs). After installing UV-C, the incidences of TB and other diseases were greatly reduced.

Other applications include food production, where many meat merchandizing and packing plant contractors turned to UV-C to spot reduce levels of microbes such as E. coli, Listeria and Salmonella. In their air conveyance systems, UV-C doesn't add much resistance to airflow, yet it can kill in excess of 99% of these and other microbes on a single pass, a major advantage in food processing plant ventilation.

In bottling plants, UV-C is used to kill microorganisms that contaminate newly formed bottles and bottling caps. By adding UV-C into the blow-molding and capping areas, bottlers don't unknowingly incorporate live microbes into their products. Similarly, UV-C lamps are used in a variety of bakeries to reduce levels of airborne yeast and mold so that live microbes are not packaged with finished goods. Beneficial side effects of UV-C help the food industry increase yield, shelf life and product quality.

In the 1960s, hospitals also began using UV-C in isolation room ductwork, as well as in self-contained recirculation systems where single pass kill ratios of infectious agents is 99.9% and higher. It is also used in exhaust systems that may contain infectious agents.

UV-C is also found in pharmaceutical industry applications to protect many different types of products, including drugs, from surface and airborne microorganisms – and in particular, injectables, where even the lowest possible number of infectious or microbial agents is catastrophic to the recipient.

Some other UV-C applications include the Pentagon for protection against bio-terror agents, the CDC for protection against catastrophic spillages of infectious agents and the isolation units at Emory University hospital where the now famous Dr. Kent Brantly and Nancy Writebol, who were both infected with Ebola, were taken to recover.

UV-C use in HVACR equipment gained popularity in the 1990s to improve indoor air quality by preventing microbial activity on cooling coils and in drain pans. However, it was its ability to lower power use that today drives nine-of-every-ten UV-C installations. It was found that UV-C eliminated accumulated organic materials in and on HVACR equipment to significantly improve airflow and heat-exchange efficiency, which not only reduced energy use, but also decreased maintenance costs while providing cleaner, healthier, odor-free air.

These and other uses of UV-C technology are often unknown and therefore under-utilized by some HVACR contractors.

The UV-C Market

Virtually all commercial HVACR systems are potential candidates for UV-C equipment because of the key benefits it offers, including: (a) destruction of surface and airborne microorganisms; (b) the restoration and preservation of refrigeration and airflow capacities to "as-built" conditions; (c) increased yield, shelf life and product quality (d) greatly improved indoor air quality; (e) reduced maintenance.

Virtually all commercial HVACR systems are potential candidates for UV-C equipment because of the key benefits it offers, including: (a) destruction of surface and airborne microorganisms; (b) the restoration and preservation of refrigeration and airflow capacities to "as-built" conditions; (c) increased yield, shelf life and product quality (d) greatly improved indoor air quality; (e) reduced maintenance.

According to many sources, the market size for Ultraviolet technology in the US is in the billions of dollars. For the most part, HVACR contractors control these markets just as they do with other ancillary products shown to be of benefit to their customer base. Just as no one would operate an HVAC system without air filters -- the time is coming when no one will operate HVACR systems without UV-C installed.

Energy Savings

It is generally agreed that as AC/R equipment ages, its ability to remove heat is compromised. This mostly results from the buildup of contaminants on heat exchangers. A fouled coil is not always obvious by appearance alone, especially recently cleaned coils, but if a system no longer handles the load, the coil is likely a fouled.

Checking airflow and comparing it to the original design is helpful. When combined with the air entering and leaving wet bulb temperatures (see the equation below), it shows that dirty coils negatively impact temperature differentials (TD or Δt) across the coil. This often results in higher air leaving wet bulb temperatures or less water being removed from the air. And, less airflow and higher space humidity will usually bring about poor IAQ levels and occupant complaints.

On average, adding UV-C to existing HVACR systems can reduce energy consumption by up to 35 percent, while improving airflow and comfort levels. UV-C by itself doesn't save energy; rather, it restores coil and/or airflow performance to its original capacity. The energy wasted to compensate for lost capacity is returned in the form of lower power consumption, and the potential dollar savings can be significant!

System capacity penalties are easily seen in the ASHRAE equation: Btu's (capacity) = CFM · 4.5 · (h1 - h 2) where h1 and h 2 are air entering and air leaving wet bulb temperatures in "Btu's per degree." In the equation, we also see that if CFM is reduced, capacity is further reduced. Working the numbers shows that even small changes in either can have a dramatic effect. In other words, both conditions "must" remain at as-built parameters for a system to "perform as originally designed."

Increased energy use in direct expansion (DX) systems occurs at the compressor and fan, and system run times often dramatically increase. In chilled water systems, added energy is used to make lower water temperatures and to increase refrigerant volume (pumps). At the air handler, fans are sped up or VFD's adjusted to overcome higher coil pressure drops and/or reduced temperature differentials.

Users report that UV-C installations are very cost effective. Most see paybacks in less than six months on energy use alone. When coil cleaning and other reductions in maintenance, occupant complaints and call-backs are factored in, payback times are reduced further. They also report that UV installations cost no more, and sometimes less, than a professionally executed coil cleaning.

ASHRAE Recommendations

ASHRAE has extensively published the benefits of UV-C in its 2008, 2011 and 2012 Handbooks. In Chapter 60.8 of the 2011 Handbook, ASHRAE established minimum irradiation levels for cooling coils to, and we quote: 1) "eliminate mold and bacteria," 2) "reduce and/or eliminate coil cleaning," and 3) "sustain coil performance." Further, it states "use of UV-C can increase airflow and heat-transfer coefficient and reduce both fan and refrigeration system energy use." These benefits were found to be obtained using 50-100 µW/cm2 (microwatts per square centimeter) striking all areas of a coil.

Properly Sizing UV Installs

Using ASHRAE recommendations, contractors can use properly marked UV-C lamps and published lamp data to determine the minimum number of lamp watts required to achieve these benefits. Lamps are typically installed about 12" from a coil's surface; although, field experience has verified that distances from 3" – 30" will work fine. Achieving 100 µW/cm2 at the farthest away corners of a coil will result in higher energy in the middle. This excess UV-C energy is good for the user as it increases the killing of airborne microorganisms because more air typically goes through the middle of the coil.

It has been calculated that an 80 Watt, 36-inch High Output UV-C lamp meets all of the ASHRAE criteria on a 1 meter square (10.76 square foot) coil. If the lamp wattage is divided by the square footage (80/10.76) = 7.43, it's found that about "7.5 lamp watts per square foot of coil surface area" more than meets ASHRAE's recommendations. Using the 7.5W per square foot provides a simplified way then to size UV installs for most any coil, large or small.

Keeping Performance Sustainable

Keeping buildings operating at their most efficient level and sustaining that performance over the life of a building is one of today's key challenges for HVACR contractors. Sustainability refers to efficiently using energy, water and other resources throughout a building's life-cycle and:

- Be simple to maintain;

- Conserve HVAC energy;

- Maintain Indoor Air Quality;

- Maintain occupant comfort, and;

- Reduce water-use, chemical-use and their disposal

Part of the mission of ASHRAE is to use today's technologies to minimize, or eliminate the use of non-green products-chemicals, sustain energy consumption and eliminate wasteful water use. UV-C directly addresses these goals, as noted in ASHRAE handbooks.

The benefits of UV-C are expanding its market because contractors are finding that it solves many of the issues affecting their customers, whether its capacity problems, maintenance costs or indoor air quality issues. Everything written here is available to contractors who align themselves with a manufacturer who offers advice, sizing tools and online and live support. It's a needed and growing market "must have" that builds goodwill and profitable relationships with customers.

The president of UV Resources, Forrest Fencl is an ASHRAE Fellow, formerly an ASHRAE Distinguished Lecturer, and a member of the International Ultraviolet Association and the Illuminating Engineering Society. He may be reached at forrest.fencl@uvresources.com.

The president of UV Resources, Forrest Fencl is an ASHRAE Fellow, formerly an ASHRAE Distinguished Lecturer, and a member of the International Ultraviolet Association and the Illuminating Engineering Society. He may be reached at forrest.fencl@uvresources.com.

Virtually all commercial HVACR systems are potential candidates for UV-C equipment because of the key benefits it offers, including: (a) destruction of surface and airborne microorganisms; (b) the restoration and preservation of refrigeration and airflow capacities to "as-built" conditions; (c) increased yield, shelf life and product quality (d) greatly improved indoor air quality; (e) reduced maintenance.

Virtually all commercial HVACR systems are potential candidates for UV-C equipment because of the key benefits it offers, including: (a) destruction of surface and airborne microorganisms; (b) the restoration and preservation of refrigeration and airflow capacities to "as-built" conditions; (c) increased yield, shelf life and product quality (d) greatly improved indoor air quality; (e) reduced maintenance.

The president of UV Resources, Forrest Fencl is an ASHRAE Fellow, formerly an ASHRAE Distinguished Lecturer, and a member of the International Ultraviolet Association and the Illuminating Engineering Society. He may be reached at

The president of UV Resources, Forrest Fencl is an ASHRAE Fellow, formerly an ASHRAE Distinguished Lecturer, and a member of the International Ultraviolet Association and the Illuminating Engineering Society. He may be reached at