If your company already counts inventory, it’s worth considering taking the next step.

Inventory is a bet. You bet your hard-earned dollars that when you pay for a part, you will be able to sell that part. Over the years I’ve seen some great bets placed in warehouses where owners track parts and don’t buy more than is prudent. Trucks are restocked from invoices or material sheets. I’ve also seen some terrible bets where there are parts purchased years ago still sitting on shelves, and service technicians’ trucks are holding damaged or obsolete inventory.

Tracking inventory and counting it once per year (or more often) takes time, labor, and money. Barcoding, which has been used in supermarkets for years, has evolved into one of the most efficient ways to track inventory for all types of businesses.

Should you take the step to barcode your inventory?

You should already be including inventory on your balance sheet. This is a basic and sound business practice. I’ve seen too many contractors not account for inventory or just record the same value for inventory each month. If you haven’t started tracking inventory so you see what a real bottom line is, then you aren’t ready for barcoding.

You also might already be using barcoding without knowing it. Some suppliers stock your shelves with inventory, and you pay for parts and supplies as you use them. You agree to purchase a minimum amount of inventory from that supplier. If you are in this situation, your inventory already is barcoded. That’s how you get an invoice for a part when it leaves the shelf.

Barcoding is probably right for your company if:

- You track your inventory but are losing tens of thousands of dollars each year.

- Your company has grown to five trucks or more, and you track inventory.

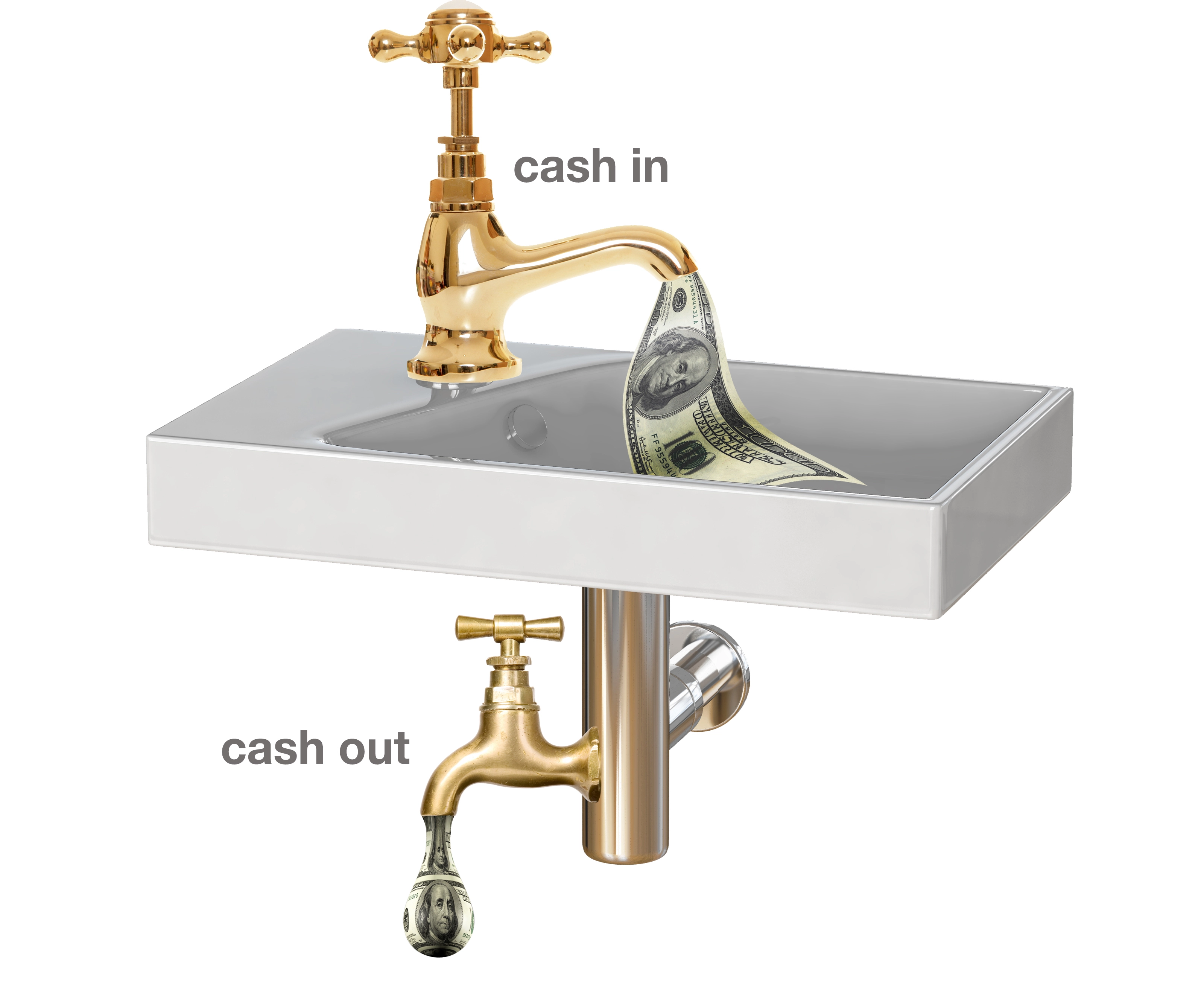

- It’s taking more and more time to count inventory, and it is tying up more of your company’s precious cash.

Another clue — your office personnel have a hard time keeping up with the number of service tickets and job-cost sheets. So what could barcoding do for your company?

- You’ll know what inventory you have on hand at all times.

- You’ll know where that inventory is (in the warehouse, on a truck, etc.)

- You’ll be able to receive, store, and move inventory on to trucks and off of trucks quickly.

- Technicians won’t have to write as much. They use a wand or simply put the barcode sticker on their paperwork.

- There will be fewer mistakes. An office person would have no trouble reading a barcode, but they could have trouble reading field personnel’s handwriting.

- You’ll have pertinent, up-to-date reports about stock levels, usage, and reorder quantities for all parts.

- Counting inventory will be much easier and quicker.

Many of our industry’s business software packages have barcoding software as part of their solutions. There are also add-on barcoding software packages that integrate with accounting software. Get references from companies in our industry that use a particular solution if you are considering using it. Also, make the barcoding transition in a slower time of the year.

At year end, when you are counting inventory, is one of the best times to make the transition. Implementing the field portion of barcoding will take time. Your warehouse shelves need to be barcoded as do the parts on those shelves.

Many times for smaller parts, the barcode goes on the shelf rather than the part. The field trucks must be cleaned out, and all parts barcoded. Decide what you will do with the obsolete inventory that you find on the trucks and on the shelves. Sometimes you can donate it to a technical school or sell it online.

I’ve also seen “garage sales,” where contractors get rid of unwanted inventory. If you don’t want the technicians to have wands in their trucks, they can have a peel-off sticker that they put on their service tickets. Implementing barcoding takes time. However, once it is implemented and used correctly, you’ll be making much better inventory bets, saving time and — as a result — increasing profitability.

Ruth King has over 25 years of experience in the hvacr industry and has worked with contractors, distributors, and manufacturers to help grow their companies and become more profitable. She is president of HVAC Channel TV and holds a Class II (unrestricted) contractors license in Georgia. Ruth has written two books: The Ugly Truth About Small Business and The Ugly Truth About Managing People. Contact Ruth at ruthking@hvacchannel.tv or 770.729.0258.