Tips for re-thinking your pricing policy.

Should I raise my prices? The real question should be: What’s going on in my company? To find the answer, look to your financial statements.

When you go through your financial statements and see that your company is earning less profit than it did in previous years, is not profitable, or a combination of both, the “Should I raise my prices?” question often pops into your head. The answer to that question: “It depends.”

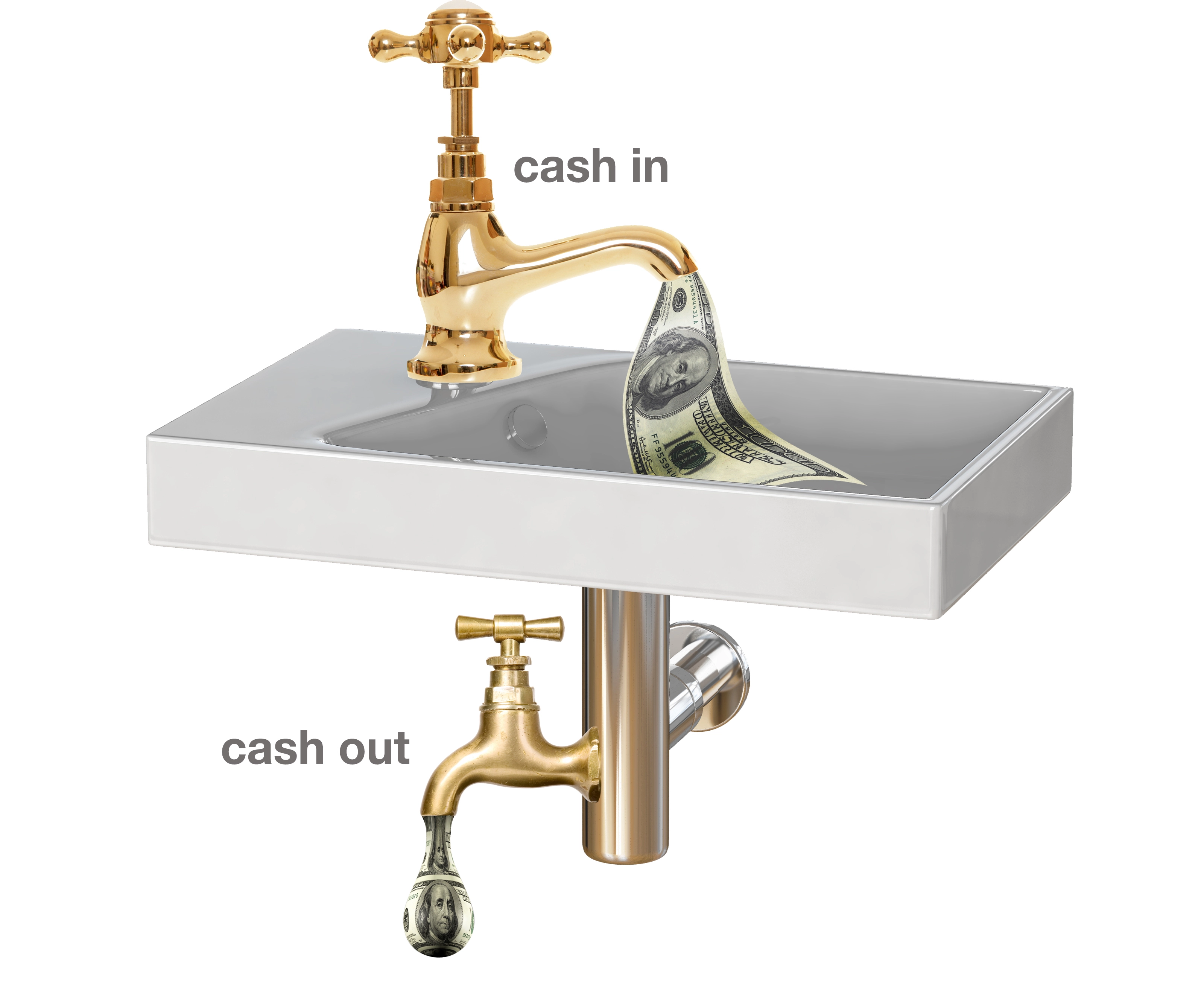

If your company was profitable last year and is showing decreasing profitability because of increasing gasoline prices, then raising your labor prices might not be the answer. Many contractors are now adding a fuel surcharge to each invoice and each job. Is that raising prices? Essentially, yes. However, it is raising prices in an area where people expect you to raise them— vehicle costs; not labor costs. With the fuel surcharge, most contractors have stated that they will decrease or eliminate the surcharge if gasoline prices decrease.

I’ve also seen contractors change manufacturers to decrease equipment pricing. With lower equipment pricing, they keep the sales price the same and their profits increase.

If your company was not profitable last year, then the question, “What’s going on?” really applies. Raising prices might not be the answer. Increasing productivity, increasing sales closing rates, increasing marketing expenditures (in the right categories) might be the answer.

Increasing productivity requires that you first examine how productive your labor force is currently. Is each technician billing at least $600 per day ($150,000 per year)? If your technician’s time sheet says he worked eight hours, did he bill eight hours to customers? Did he bill four? If he billed four or is not generating at least $600 per day on average, then you probably have a productivity problem. Proper dispatching, routing, and tickler files can help increase productivity. In the past I’ve written about tickler files— a copy of the invoices where a technician recommended repairs or maintenance that the customer chose not to have done at the time. These are a ready list of work when you don’t have 40 hours of work for your technicians with incoming calls. Educating the customer about maintenance agreements, IAQ products, and other products that can help the customer will increase service-ticket revenues.

Were your installation crews on the job for eight hours? Did you get them out of the shop in less than 15 minutes? Did they stop at the donut store on the way to the job, have breakfast, and charge the job for it? Did they have one hour left on a job and quit rather than finishing it with one hour of overtime? Better they finish that day. It will take more time than one hour to finish the next day. These are quick ways to immediately increase productivity.

If your sales closing rate is less than 30%, it’s time to take a sales class. HVACR Business columnist Tom Piscitelli has some good ones and has a proven track record in increasing sales and closing rates.

Continuous marketing is critical for lead generation — both service and installation. Even in the tough times you should continue marketing to your existing customers. Remind them why they need your services — to save money, decrease utility costs, etc.

If your field labor productivity is higher than 80%, your sales closing ratio is higher than 40% and you execute a continuous marketing plan, yet your financial statements are still showing lower profitability, then the answer to the question, “Should I raise my prices?” is probably yes. The next question: “How much?”

Some contractors I know raise their rates at the rate of inflation, at a minimum, each year. Their employees want raises. Their suppliers increase their pricing. They pass these increases along to the customer and justify those increases by continuing to provide high quality service/installation and communications.

From an installation standpoint, the “How much?” answer depends on the increases in your direct costs and overhead costs. For replacement pricing, when you use a net-profit-per-hour calculation, the pricing increases are easily calculated. Assuming that you want your net profit per hour to be consistent, add the overhead cost per hour, the total direct cost per hour, and the profit per hour you desire to arrive at the selling price per hour. The total price is the selling price per hour times the total number of hours for each job. This assumes that you accurately determine the number of hours for each job.

Ruth King has over 25 years of experience in the hvacr industry and has worked with contractors, distributors, and manufacturers to help grow their companies and become more profitable. She is president of HVAC Channel TV and holds a Class II (unrestricted) contractors license in Georgia. Ruth has written two books: The Ugly Truth About Small Business and The Ugly Truth About Managing People. Contact Ruth at ruthking@hvacchannel.tv or 770.729.0258.