Over the past few years I've seen contractors make huge mistakes that cost them thousands of dollars because they didn't estimate the cost of their jobs properly. I've also seen many contractors stake their pricing on the "Gross Margin" method.

Dividing costs by 100% minus gross margin percentage only works when your job is 50% labor and 50% materials. Most residential replacement jobs don't have equal costs of labor and materials. That's why you can price your job out of the market and other times, for high labor jobs, lose your shirt.

Commercial contractors have been using dual overhead for years. They recognized that there are different costs associated with materials and labor. The dual overhead method works and many commercial contractors have made millions using it. However, most of our industry, especially residential contractors, rely on the gross margin method which is actually less accurate than the dual overhead method.

There is another method that has been used very successfully for a number of years and which, in my opinion, is more accurate. This method looks at the gross profit per hour, the overhead cost per hour, and the net profit per hour that you want to earn. It explains how, in slower seasons, contractors can seemingly price a job "so low" that you can't match the price. However, they know what their total cost of the job is before profit and have decided to break even on the job rather than make profit. That is a business decision you can make once you know what your costs truly are.

Net profit per hour calculations rely on an accurate labor estimate. If you estimate a job at 16 hours and it comes in at 12 hours, you've made more profit. If you estimate a job at 16 hours and it comes in at 18 hours, a break even job turns into a loss. Labor estimates are critical!

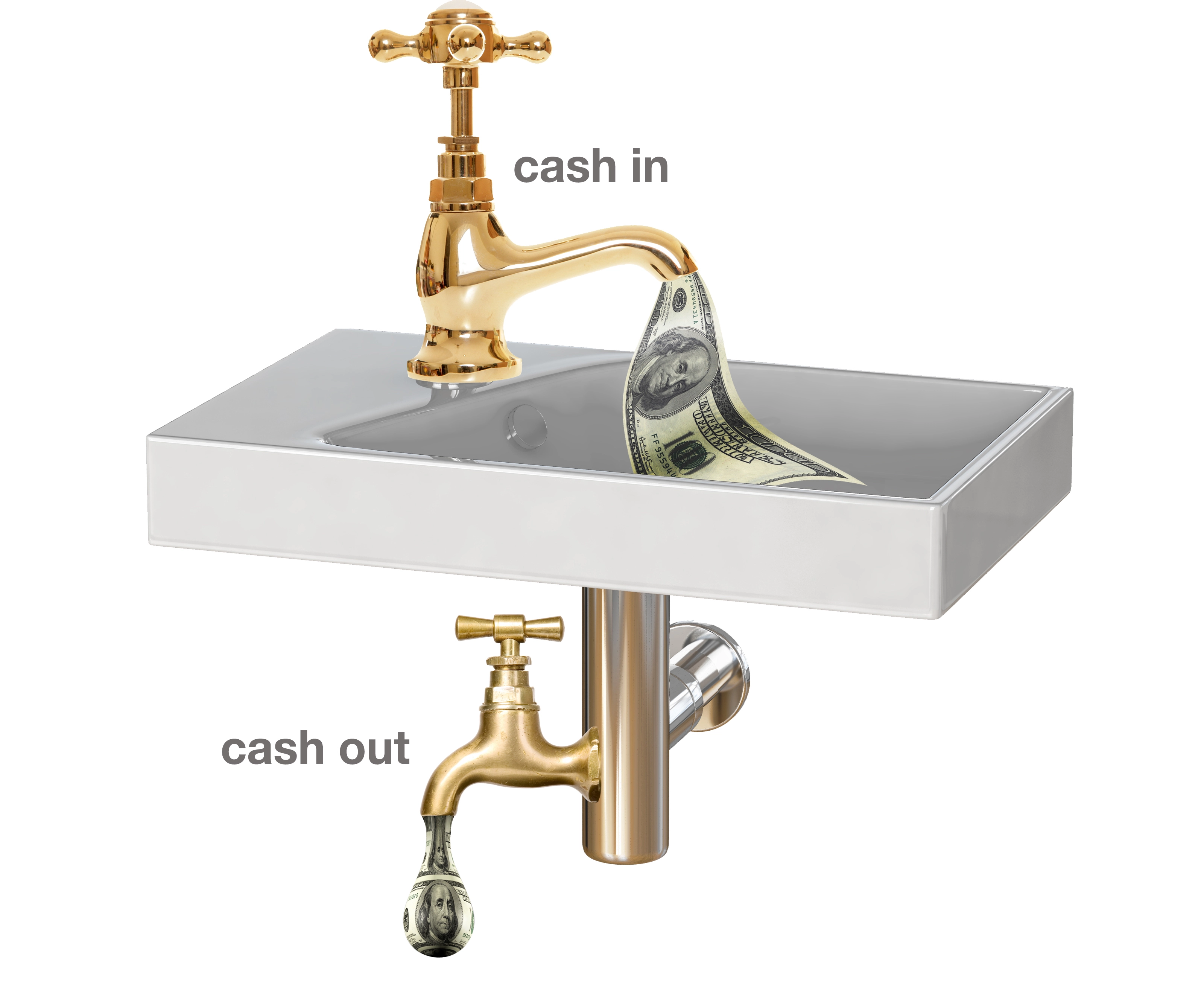

Calculating a sales price conceptually is very simple. You estimate your total direct costs for the job (labor, materials, commissions, warranty, taxes, shipping, service agreement, subcontract labor, etc.). know your overhead cost per hour. Multiply overhead cost per hour times the total number of estimated hours on the job to get total overhead applied to the job. Then, add the overhead to the total direct cost to get total cost of the job. Finally determine how much profit you want to earn on the job. You then have your price to the customer.

Calculating direct cost is easy. Calculating overhead cost isn't. You have to determine the yearly overhead for each department and then divide it by the number of revenue producing hours per year.

Departmentalization gets tricky. There is no one exact way of doing it. I've summarized it here (the details are in my article in the February 2005 issue of HVACRNews and also available on HVACR Business' new website under the "Finance" tab).

Either people cause overhead or space causes overhead.

First the space issues. There are only five things that cause space expenses; rent, utilities, building maintenance, building taxes, and building insurance. Determine the total amount of productive space used by each department. Productive space is the space occupied by either people or things related to revenue producing departments. For example, your bookkeeping space doesn't count; your reception space doesn't count. The space that is used by financial people or other people who are not out producing revenues do not count in this equation.

For example, if you have a 5,000 square foot building and of that 5,000 square feet, 1,000 are being used by service and replacement and 3,000 are being used by new construction, that is a total of 4,000 square feet that are productive. 25% of the space overhead costs are assigned to the service department and 75% of the space related overhead costs are assigned to new construction. If rent is $1,000 then the service department gets $250 for rent and new construction gets $750.

Next, people issues. Every other overhead item is really related to people. The more people you have the more office supplies you have. The more people you have the more telephone calls that you have. In addition, if you know the exact amount of time that somebody spends in a particular department, then take that percentage rather than the overall estimate. If you have a bookkeeper who is splitting her time between service, new construction and electrical you may need to determine how much time she is spending in each one of the departments on their tasks and then allocate her salary appropriately. If things are bought only for one department then that department gets 100% of that expense.

For overhead items that are split, you must determine the total amount of productive payroll, i.e. field personnel payroll. Then, if the total productive payroll is $100,000 and the service productive payroll is $50,000, new construction's productive payroll is $20,000 and replacement is $30,000, the service department gets $50,000 over $100,000 or 50%, new construction gets $20,000 over $100,000 or 20%, and replacement gets $30,000 over $100,000 or 30%.

Then, calculate the total overhead for each department using either space or people percentages for each overhead item. Spread sheets can help you make the calculations easily.

Once you have the overhead cost for each department you need to find the productive payroll for each department. Productive Payroll is the total number of revenue generating hours. It does not include any hour that you cannot bill a customer for. Training hours don't count. Travel hours don't count unless you bill them to the customer. Running to the supply house hours don't count unless you can bill them to the customer.

Then to determine total overhead cost per hour, divide total overhead for the department by the total revenue producing hours for the department.

Next month I'll give you examples of each calculation and how to better price your jobs.